Features:

The HDY series hydraulic hammer, which matches the E and D series

power stations, is the latest energy-saving and environmentally

friendly foundation construction equipment developed by our

company. It adopts multiple advanced hydraulic and electrical

control technologies, with characteristics such as low noise, no

pollution, high efficiency and energy saving, safety and

reliability, and easy operation. Suitable for hammering

construction of prefabricated pipe piles and steel pipe piles with

different geological conditions and requirements, the D550 power

station can also be matched with vibration hammers for

construction, making it an ideal new generation of piling

machinery.

The hydraulic system has high efficiency, with a rated working

current of about 200~250A, and can be equipped with 120~150 square

aluminum cables.

The cable has a small cross-sectional area and is lightweight,

greatly reducing the labor intensity of workers; HDY25 hydraulic

hammer is equipped with Dongfeng Cummins QSZ13-C550 diesel engine,

two Rexroth A11VLO260 plunger pumps and one Parker T67DB double

blade pump connected in series to form a pump set, providing

surging power for construction;

Adopting the international first-class brand Rexroth main oil pump

and valve, with good stability, high reliability, and high

efficiency and energy saving;

Adopting the international first-class brand Hedeke oil return

filter, with high flow rate, high filtration accuracy, and low oil

return resistance, it can

effectively improve the cleanliness of the system oil, reduce

equipment failure rate, and extend equipment service life;

The hydraulic cylinder of the pile driver adopts international

first-class brand Trelleborg seals, which have low failure rate,

high efficiency, and long service life;

Adopting a high-power three in one oil cooler, coupled with a

temperature controller to accurately control the oil temperature,

completely solves the problem of high oil temperature in hydraulic

pile driving, significantly improves pile driving efficiency, and

effectively extends the service life of seals and hydraulic oil;

The power station adopts a high-level fuel tank and internal forced

ventilation design to improve oil pump suction, oil pump motor,

electrical cabinet or engine heat dissipation.

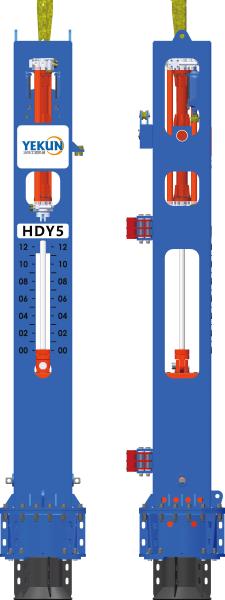

Main Structure and Appearance:

The HDY series hydraulic hammer is composed of mechanical parts,

hydraulic system, and electrical system. The mechanical part is the

main body of the hydraulic hammer, which performs external work on

the hammer. The hydraulic system is the power source of the

hydraulic hammer, while the electrical system is the energy input

and control center of the hydraulic system.

The mechanical part consists of the hammer core assembly, hammer

body assembly, oil cylinder assembly, upper pile cap, lower pile

cap, hammer pad, pile cap buffer ring, landing gear, etc. The

landing gear is used for the ascent and descent of hydraulic

hammers; The hammer body is the supporting body of the entire

mechanical part, used to support the oil cylinder and hammer core;

The upper pile cap is fixed at the bottom of the hammer body, and

the lower pile cap is sleeved inside the upper pile cap to support

the pipe pile and transmit the impact force; The hammer pad and

pile cap buffer ring are fitted onto the lower pile cap to achieve

energy transfer between the hammer core and the pipe pile; The oil

cylinder assembly of the hydraulic hammer achieves the lifting of

the oil cylinder piston and the acceleration of gravity through the

opening and closing of the plug-in valve installed on the valve

block of the oil cylinder. The opening and closing of the plug in

valve is controlled by the solenoid valve and sequence valve

installed on the valve block of the oil cylinder.

The hydraulic system mainly consists of a power station, oil pipes,

oil cylinders, etc.

The electrical system mainly consists of four parts: controller,

electronic control box, sensors, and engine.

Product Parameter:

| Model | Unit | HDY5 | HDY8 | HDY10 | HDY12 | HDY14 | HDY16 | HDY18 | HDY20 | HDY22 | HDY25 |

| Maximum strile energy | KN.m | 60 | 120 | 150 | 180 | 210 | 240 | 270 | 300 | 330 | 375 |

Maximum stroke of the

hammer core | mm | 1200 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 |

| Strike frequency bpm | bpm | 30-80 | 30-80 | 30-80 | 30-80 | 30-80 | 30-80 | 30-80 | 20-70 | 20-70 | 20-70 |

| Weight of sriking body | kg | 5000 | 8000 | 10000 | 12000 | 14000 | 16000 | 18000 | 20000 | 22000 | 25000 |

| Total height A | mm | 5930 | 6230 | 6750 | 7270 | 7670 | 7670 | 8020 | 7920 | 8220 | 8620 |

| Total height B | mm | 6960 | 7260 | 7760 | 8430 | 8830 | 8830 | 9180 | 9080 | 9380 | 9780 |

| Front and rear width C | mm | 1400 | 1520 | 1520 | 1460 | 1460 | 1490 | 1490 | 1720 | 1720 | 1720 |

| Left and right width D | mm | 1140 | 1260 | 1260 | 1260 | 1260 | 1260 | 1260 | 1500 | 1500 | 1500 |

| Hydraulic hammer weight | kg | 9450 | 12650 | 15200 | 20200 | 22600 | 24650 | 27100 | 32350 | 34680 | 38000 |

| Landing gear weight | kg | 200 | 200 | 500 | 500 | 650 | 650 | 650 | 870 | 870 | 870 |